|

| Features :- |

| 100% Leak Proof Pumps Due to Magnetic drive arrangement. No shaft Seal used which automatically solves problems of seal leckage and wear & tear. Friction free operation for reduced power consumption. High Power permanent magnets ensure full power transfer and eliminates slippage. All pumping parts Non-metallic, which gives superior corrosion resistance. Simple and easy to operate and maintain. Long life, reliable and trouble free operation. |

| |

| Application & User Industries :- |

| Ideal for transfer of corrosive chemicals, acids, dyes, solvents, toxic & fuming liquids, petrol, kerosene etc. Useful in Chemical industries, Pharmaceuticals and Food processing industries. Electroplating, Galvanizing/ anodizing plants. Laboratory equipments and PCB plants. Medical equipments and X-Ray film plants. Textile Dyeing houses. Liquid dispencing machines and Chemical Filtration equipments. For hazardous duty conditions with flame proof motors. |

| |

Series MDP :- Seal-less Magnetic Drive Pumps with 100% Leak Proof design. Suitable for highly corrosive liquids, toxic & hazardous liquids. High Power permanent Rare Earth Magnets. All Wetted parts of Polypropylene.

| Specifications |

| Pump Model |

In/Out Size |

Max. Capacity LPM |

Max. Head Mtrs |

Motor HP |

Full Load Current |

Phase |

Sp. Gr. Limit |

Weight |

| MDP-15 |

14 MM |

15 |

2.5 |

0.10 |

0.15 Amps |

SINGLE |

1.1 |

3 Kgs |

| MDP-30 |

18 MM |

30 |

4 |

0.16 |

0.20 Amps |

SINGLE |

1.1 |

3.5 Kgs |

| MDP-50 |

20 MM |

50 |

5 |

0.25 |

0.50 Amps |

SINGLE |

1.2 |

5 Kgs |

| MDP-85 |

26 MM |

85 |

9 |

0.50 |

1.00 Amps |

SINGLE/ THREE |

1.2 |

8 Kgs |

| MDP-125 |

26 MM |

125 |

12 |

0.75 |

1.25 Amps |

SINGLE/ THREE |

1.3 |

10 Kgs |

| MDP-170 |

1" BSP |

170 |

14 |

1.0 |

1.70 Amps |

THREE |

1.3 |

12 Kgs |

| MDP-300 |

1½" X 1¼" |

300 |

22 |

1.5 |

2.40 Amps |

THREE |

1.4 |

16 Kgs |

| MDP-500 |

2" X 1½" |

500 |

32 |

3.0 |

4.70 Amps |

THREE |

1.5 |

30 Kgs |

|

| * |

All pumps are rated for continuos duty with class E Insulation. |

| * |

Max operating Temp -80°C for PP, 150°C for PVDF & 250°C for SS-316. |

| * |

All pumps are Centrifugal Semi-open impeller type pumps and need priming before start up. |

| * |

SS-316 Magnetic pumps are avaliable upto 5 HP. |

|

| |

| |

|

Stainless Steel (SS 316) Magnetic Drive Pumps |

| Features :- |

100% Leak Proof Pumps Due to Magnetic drive arrangement. No shaft Seal used which automatically solves problems of seal leckage and wear & tear. Friction free operation for reduced power consumption. High Power permanent magnets ensure full power transfer and eliminates slippage. |

|

| |

| Application & User Industries :- |

| Ideal for transfer of corrosive chemicals, acids, dyes, solvents, toxic & fuming liquids, petrol, kerosene etc. Useful in Chemical industries, Pharmaceuticals and Food processing industries. Electroplating, Galvanizing/ anodizing plants. Laboratory equipments and PCB plants. Medical equipments and X-Ray film plants. Textile Dyeing houses. Liquid dispencing machines and Chemical Filtration equipments. For hazardous duty conditions with flame proof motors. |

| |

|

| Series SMD :- Seal-less Magnetic Drive Pumps with 100% Leak Proof design. Suitable for highly corrosive liquids, toxic & hazardous liquids. High Power permanent Rare Earth Magnets. |

| |

Specifications of SS-316 Magnetic Drive Pumps :- |

| Pump Model |

Motor HP |

In/Out Size |

Max. Capacity in LPM |

Max Head in Mtrs |

| SMD-01 |

0.5 |

12 X 12 |

30 |

10 |

| SMD-02 |

0.75 |

25 X 25 |

80 |

15 |

| SMD-03 |

1 |

25 X 25 |

150 |

28 |

| SMD-03A |

1 |

40 X 40 |

270 |

18 |

| SMD-04A |

2 |

40 X 40 |

180 |

26 |

| SMD-04B |

2 |

50 X 40 |

300 |

22 |

| SMD-05A |

3 |

50 X 40 |

250 |

30 |

| SMD-05B |

3 |

50 X 50 |

340 |

24 |

| SMD-06A |

5 |

50 X 40 |

250 |

38 |

| SMD-06B |

5 |

65 X 50 |

575 |

25 |

| SMD-07A |

7.5 |

50 X 40 |

280 |

48 |

| SMD-07B |

7.5 |

65 X 50 |

650 |

36 |

| SMD-07C |

7.5 |

80 X 80 |

1000 |

22 |

| SMD-07E |

7.5 |

80 X 65 |

800 |

32 |

| SMD-08A |

10 |

50 X 40 |

300 |

55 |

| SMD-08B |

10 |

65 X 50 |

750 |

40 |

| SMD-08C |

10 |

100 X 80 |

1300 |

25 |

| SMD-09A |

12.5 |

50 X 40 |

520 |

55 |

| SMD-09B |

12.5 |

65 X 50 |

725 |

48 |

| SMD-09C |

12.5 |

80 X 65 |

1250 |

42 |

| SMD-10A |

15 |

80 X 65 |

1050 |

45 |

| SMD-10B |

15 |

100 X 100 |

1800 |

32 |

| SMD-11A |

20 |

65 X 50 |

440 |

70 |

| SMD-11B |

20 |

80 X 65 |

1050 |

55 |

| SMD-11C |

20 |

100 X 100 |

1900 |

38 |

|

|

| |

| * |

All S.S Magnetic Drive Pumps are made of SS-316 |

| * |

Magnets used are of High Power Permanent Rare earth magnets |

| * |

The motor used in all above models is of PEW (Mumbai) make |

| * |

Performence given above based on our test results with water at normal condition. Actual site performence |

| |

may vary due to change in liquid parameters |

|

| |

| |

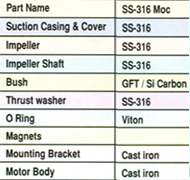

| Material of Construction |

About Magnetic Pump |

|

|

Magnetic drive design eliminates the conventional method of shaft coupling. Hence the pump casing is fully sealed from drive end which gives away the use of conventional sealing system. There is no seal used and hence no troublesome seal repairing and replacement, leckage and production lost. Impeller and drive magnets are permanent rare earth magnets. They prevent slippage and ensure that full motor horsepower is converted into pumping power.

|

Back to Home Page

|

|

|